Resilience.

Business resilience is your organisation’s ability to quickly adapt to changes while continuing business operations and safeguarding your people and assets. This is exactly the capability your company will need in the face of economic headwinds.

If you haven’t made your company resilient before the headwinds hit, it will be too late.

In the mining industry, economic headwinds include

- Changing commodity prices, this includes rising commodity prices because they are associated with supply chain cost increases (e.g. scarcity of tyres, spares, labour, and even fuel prices).

- You might experience a situation where resource data, which had previously been thought to be reliable, now turns out to be inaccurate or incomplete or incorrect.

- During the boom times, there is increased competition to attract and keep the best talent.

- Governments making environmental compliance requirements more stringent.

- Or, hell, it might even be a global pandemic. Who would have anticipated that?

A few years back, we had just helped one of our clients complete their digital transformation, moving all of their physical reporting, collaboration and action management tools and processes to the cloud. When the COVID-19 pandemic hit, they were in a much better place than their counterparts. They sent their engineers off-site, who continued more or less as they had before, while running skeleton crews on-site.

Business resilience helps you not only survive such challenges but perhaps even thrive when others falter. So how do you make your company resilient, and preferably quickly?

As the business leader, the first thing you require is the ability to recognise the need for change before it’s too late. You must be able to trust your information, accept the facts, and commit.

For this, you need the awareness of what’s happening inside and outside of your company.

1. Early warning systems of trouble ahead

This is where your Business Intelligence (BI) — your dashboards, reporting, and analytics — will have to ratchet up a notch.

- Is the information trustworthy? The number of people we meet who are involved in capturing data and do not trust it themselves is staggering.

- Why don’t the people closest to the data trust it? I’m going to answer this question with another question: Which one is the single source of truth? Sit in any typical Daily Production Meeting and watch how the production, engineering, mechanical and electrical maintenance reps can’t even agree on what the right downtime numbers are. We often find the same for actual production figures, as they are usually tracked on numerous platforms and often not one of them is the official one. So everyone rolls with their own numbers! Yes, every site has a formal reconciliation process but it’s only as good as the garbage in, garbage out (GIGO) process allows it to be.

- The solution to this is surprisingly simple: ensure that there is agreement on the data collection process, there is a daily reconciliation process between the various functions, what the single source of truth is and who owns which data. These people then become accountable for data accuracy and timelines.

- Does your BI help you predict the future or simply confirm the past? If your BI system mostly focuses on historical information, your ability to predict the future will be limited to scrutinising trends. On the other hand, if your team starts measuring the health of your systems and processes, they will be able to deal with any deviations before they become problems and impact the bottom line.

- Do your teams all agree on what their end-to-end process steps really are? Hint: If these aren’t properly documented then what we’re talking about is opinions.

- Are upstream metrics monitored so their health can be tracked before they impact their downstream ‘customers’?

- Again, the solution is not rocket science: ensure the processes are mapped across functions and they think of every step in a process as both a supplier (upstream) and a customer (downstream). What are some of the metrics these customers require to be effective? For example, we have seen mining operations where the quality of the dozer operation before handing over to drill and blast was more often than not so poor it had to be redone, impacting schedule compliance every single time. Similarly, the quality and timeliness of engineering output (e.g. ’stope notes’ or whatever your company calls it) impacts downstream ‘customers’ (production in this case) far too often.

- You manage what you measure — once these steps are understood, standards agreed and tracked and poor performance is put in the spotlight they start to improve and so does efficiency. Cost per production unit drops, making you leaner and more competitive.

As commodity prices drop you cannot afford to be inefficient.

I cannot overstate the importance and benefits of making sure your teams are providing you with accurate data; analysing rubbish data is a waste of time! The examples above illustrate some of the benefits associated with simply increasing data accuracy, trustworthiness and an increased focus on leading metrics (see also The Only Metrics And KPIs A Mining CEO Should Care About).

2. Accurate troubleshooting. Finding the real causalities, quickly

Left to their own devices, systems have a natural tendency to decay, become complex and chaotic over time.

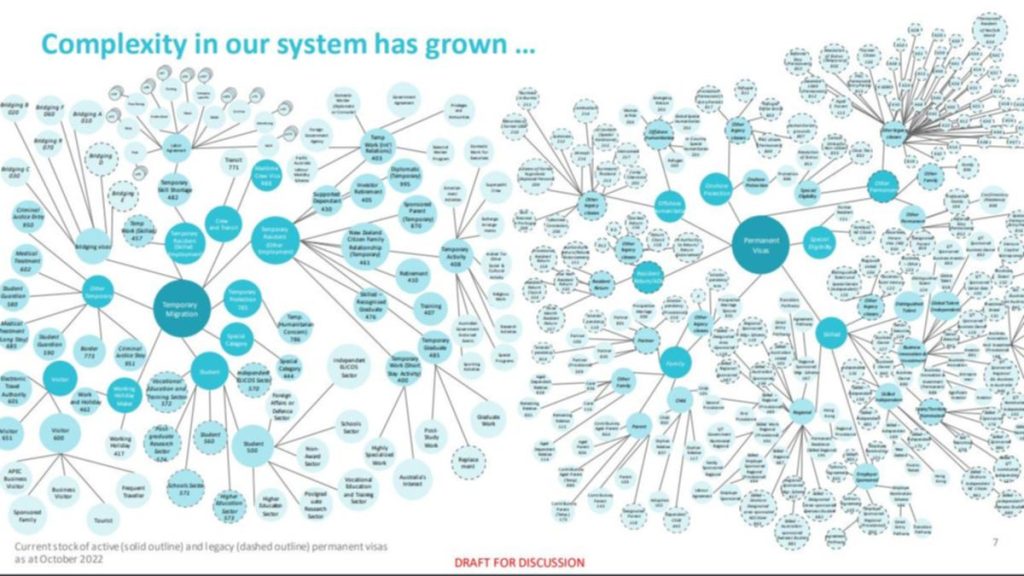

In the late 1990s, Australia’s migration system had been considered the international gold standard (AFR 2023-02-23). In 2023, Home Affairs minister Clare O’Neil presented the spaghetti diagram below, which illustrates what happened to it since then.

Programs begin with good intentions but over time, they decay and become engulfed bureaucratic complexity. It’s a problem that all organisations have in common.

Because most people prefer to work in silos, stepping outside them is difficult, unnatural and results in them operating in their own little fiefdoms.

Here’s the good news: as this is the result of poor leadership, vision and strategy it is 100% within the leaders’ control.

The opposite to chaos is order and clarity.

Order, control and clarity comes from knowing your business. Know which actions will give you the desired outcomes, not by trial and error, but because your team understands their operation.

Let me ask you again: does everyone involved agree what the process is meant to be or have the processes been allowed to metastasise? Are your processes clear, documented and have owners who are accountable for their outcomes and impacts?

Instead of an organically grown system you need a clear, coherent overarching operating model. Until you as the business leader commit to actively continually improving not simply maintaining this operating system, it will not happen. This must be one of your strategic imperatives (in the Balanced Scorecard framework, some of its components fall into the Internal Process category and some land in the Organisational Capacity category), which means you have to commit resources to it. It will also require ownership and accountability at various levels.

(I also recommend one more tool that can help your team diagnose problems quickly and accurately: the Value Driver Tree (VDT). A good VDT is like a mathematical twin of your operations and can point to root causes and produce valuable ‘what-if’ scenario options on the fly.)

OK, now that your Business Intelligence provides you with a trustworthy early warning system and your teams understand their business, they will be able to diagnose problems quickly and accurately.

Now they will be ready for the next step.

3. Implementing controlled change, efficiently

The above steps will provide clarity and flexibility, allowing you and your team to take actions confidently, knowing that they will work. If for some reason they don’t work as expected, your forward-looking BI system will let you know quickly, so you can continue and tweak the improvements. This will prepare your business for any turn in the business, which will allow you to scale up or down as required.

Of course, it’s no secret that not everyone embraces change as wholeheartedly as we’d like them to. In fact, this is where most business improvement programs fail.

Lucky for you, successfully implementing change is no longer a black art and has long become a well-understood, reliable method – but only if we choose to follow it! Change is not something to be thrown at the wall like spaghetti and see what sticks!

Depending on the scope and scale of the changes proposed, you, as the organisation’s leader, will have a direct responsibility in ensuring successful change implementation.

As the CEO, here’s what you need to do:

- Assess the impact the change will have on your people: the higher the ongoing effort required to maintain current operations, while simultaneously dealing with change, the more change support will be required.

- Commitment from you and your C-Suite team: top-level commitment is critical to gaining commitment from those at the coal face. Don’t expect your employees to change if they don’t see that the company’s leadership is backing a project.

- Provide sponsorship:

- Make yourself available to the project teams; create a steering committee of key sponsors to monitor progress; remove roadblocks

- Provide Change Management (CM) training to everyone in a leadership position

- Provide clear direction and objectives for the project; describe what success will look like

- Communicate your ‘Why’, the business drivers for change and the risks of not changing

- Define expectations and accountabilities for the C-level and site level (GMs and HODs) and hold them accountable for results; these need to be part of the business’ strategic and tactical plans

- Provide resources:

- A competent project and change team (internal or external), who follow proven Project and Change Management methods; let them develop a project plan and present it to you

- Get your managers to select some of your most respected people from various levels and areas of the business and release them from their BAU duties to become the initiative’s champions. Yes, these are the people that no one wants to let go, but they’re the ones who will ensure success because they are respected and their example is followed

- Funding for training and other expenses

- Don’t let up until the initiative has succeeded and the new ways of working have become business as usual.

I hope I’ve managed to convey a simple and proven roadmap to making your mining company more robust and resilient to any headwinds you and your team may encounter.

Note that I did not say this was easy. As the business leader, you will not be running the actual improvement project, however, are some leadership responsibilities associated, specifically with this kind of endeavour, that you cannot delegate. It calls for your authentic leadership and sponsorship, which you — and only you — can perform.

Insurance or investment?

Finally, when is the optimal time to start? Should you think of a concerted Business Improvement initiative as insurance or an investment?

When making investments, timing can be everything. And frankly, if you don’t have insurance when you need it, it’s too late.

Change takes time. If it’s done well, it can be accelerated, up to a point. Business, social, environmental circumstances can change with very little notice, so, given the lead-time, the best time to start was yesterday.

If you didn’t start yesterday, your next best option is to start today and the worst option is — you guessed it — tomorrow. Best practice is to include Business Improvement as a strategic initiative, but in reality, many operations ‘just do it’ anyway.

Conclusion

- Business resilience is crucial for mining companies to survive and thrive in the face of economic headwinds.

- To make your company resilient, you need to recognise the need for change before it’s too late and have an awareness of what’s happening inside and outside of your company.

- You will also need early warning systems of trouble ahead and accurate troubleshooting to find the real causalities quickly.

- Implementing controlled change efficiently is critical to gaining commitment from those at the coal face.

- Business Improvement initiatives are not easy but when done well, always worth your time and investment.

- The best time to start is now! By following these steps, you can make your company more resilient and better prepared for any turn in the business.